The 5 Biggest Mistakes in ADAS Calibrations (And How to Avoid Them)

Discover the 5 most common mistakes in ADAS calibrations and how to avoid them. Practical advice for garages with professional equipment.

The 5 most common mistakes in ADAS calibrations (and how to avoid them)

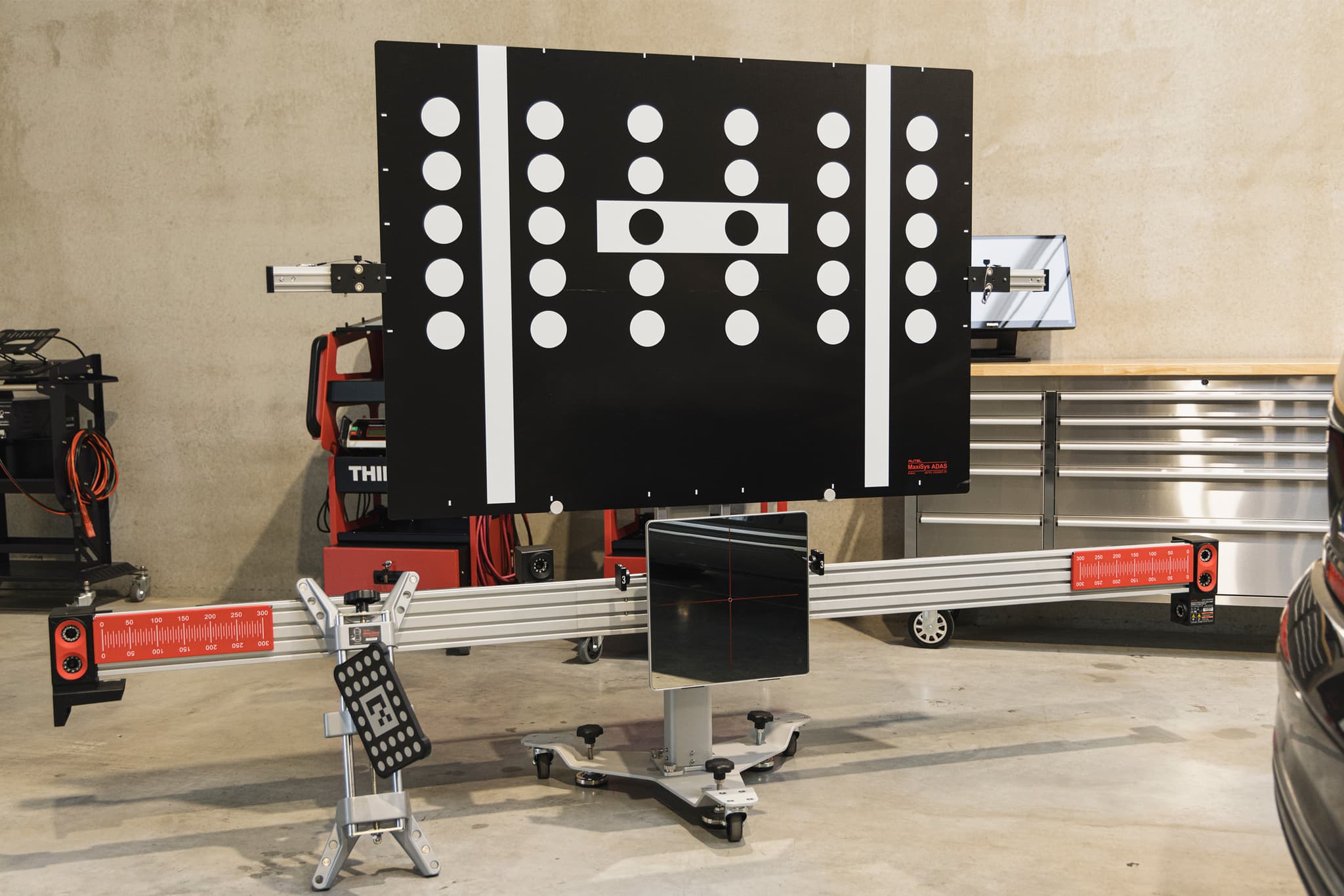

Many modern vehicles are equipped with Advanced Driver Assistance Systems (ADAS) that enhance safety and driving comfort. After repairs or sensor modifications, these systems must be accurately calibrated to factory specifications. However, many garages struggle with performing ADAS calibrations correctly, such as due to improper spacing, unfavorable lighting or incorrect calibration heights - this article helps avoid those mistakes. Moreover, all ADAS calibration devices, boards and complete sets are available from us, so you can always work with the right equipment. Below, we discuss the five most common mistakes made during ADAS calibrations and how to avoid them, so that driving assistance systems function optimally again after calibration.

1. Wrong distance to calibration target

The error: Common error is not placing the calibration target (the panel or target) at the exact prescribed distance and position relative to the vehicle. Even a small measurement error or misalignment can have major consequences: a deviation of just one degree in the calibration angle can cause a camera or sensor to miss an object on the road meters away. In other words, if the target is too close to or too far from the car (or not exactly centered), the ADAS camera or radar "looks" in the wrong direction, so to speak, resulting in erroneous or missing warnings.

Why does it happen? This error often results from haste or incorrect measurement methods. Technicians sometimes measure from the wrong reference points, or round off distances "just about right." Time pressure can also cause one to allow a few inches of slack, but ADAS systems are very sensitive to this. Manufacturers specify in their manuals exactly at what distance and height the targets should be, often with a tolerance of only a few millimeters. They do this for a reason: not calibrating to the exact distance and height prescribed by the manufacturer can mean that the ADAS system does not function properly, endangering road safety.

Measures extremely accurately: Use professional measuring instruments (e.g., lasers or calibration lasers) to determine the exact distance and angle. Strictly follow OEM guidelines for calibration target placement, including prescribed distance and angles.

Center on the center line: Always place the calibration board exactly in line with the center line of the vehicle. Most car manufacturers calibrate relative to the center line of the car for maximum accuracy. This prevents skewed calibration if, for example, the car is not perfectly straight.

Double-check distances: After setup, check with a second measurement to make sure everything is correct. Tip: Make marks on the floor according to the instructions and use a tape measure or laser to verify. Preferably also use the appropriate calibration sets - With us you will find all official ADAS targets and measurement setups, so you can be sure you are working with the right targets and distances.

2. Wrong calibration height or uneven surface

The error: Another common error is ignoring height and horizontal flatness when calibrating. This manifests itself in two ways: (a) the height of the calibration target or device is set incorrectly, and (b) the car is not on a perfectly level surface. If the calibration panel is too high or too low in relation to the sensor, or if the floor is not level, the geometry of the calibration is incorrect. A vehicle parked on a slope or a target placed a few inches wrong in height can cause the ADAS camera to misjudge reality. Even a small difference in height affects the viewing angle of a camera or radar and results in inaccurate measurements.

Why does it happen? This error often results from a lack of suitable facilities or ignorance of how critical the surface is. Not every garage has a completely level floor; sometimes calibration is done on an uneven workshop floor or a bridge that is not level. Also, height adjustment of calibration boards is sometimes done "by eye." Factory regulations, however, require that the vehicle is on an absolutely level, level surface during calibration. In addition, the calibration target must be at exactly the prescribed height above the ground - for some systems, for example, 90.5 cm, with only minimal tolerance. If this is not met, the calibration immediately becomes out of spec.

How do you prevent this?

Make sure the floor is level: Perform calibrations on a completely horizontal surface. Even a slight slope can interfere with sensor alignment. Use a level to verify that the workshop floor or bridge is level. If the workshop lacks a level floor, consider a special calibration setup or alignment bench that is perfectly level.

Set the target height precisely: Use the height specified by the manufacturer for the calibration board. Accurately measure this height from the ground (for example, with a ruler or laser altimeter) and lock the calibration stand at that height. Leave nothing to chance: manufacturers expect height and distance exactly correct.

Minimize suspension influences: Make sure the vehicle is in normal ride height (not jacked up or extra load). Unusual loading or worn shock absorbers can affect the vehicle height and thus interfere with calibration. If necessary, perform a short drive or move the car to settle the suspension before starting.

3. Unfavorable lighting conditions or distracting background

The error: ADAS cameras "look" for patterns on calibration boards, so lighting conditions and surroundings must be ideal. A common mistake is calibrating in inappropriate lighting - for example, in too bright sunlight with reflections, in twilight darkness, or with bright workshop light reflecting on the board. A cluttered or busy background behind the calibration target can also confuse the camera. Poor lighting or distracting objects around the target can cause the camera to fail to recognize or inaccurately read the calibration board. As a result, the calibration may appear "complete," but the sensor is actually misaligned.

Why does it happen? This error often arises from underestimating the influence of the environment. People sometimes think that a camera is the black-and-white sign always will see. In practice, however, shadows, backlighting or glare on the floor can interfere with the pattern. Reflective floors, poor lighting or an uneven background can cause errors in target recognition. Technicians who do not have a controlled space sometimes try to calibrate outside or at a common workshop angle, which is suboptimal. Factory instructions almost always state that calibration should be done at normal to high brightness, without direct sunlight or glare. Also, the background should be neutral and free of distracting patterns (a plain wall works best).

How do you prevent this?

Calibrate in a controlled environment: Perform static calibrations preferably inside the workshop out, with constant, good lighting. Avoid bright sun or just too little light. Clear diffused light without reflections is ideal. Instructions recommend using under normal lighting to calibrate - that is, well-lit conditions similar to daylight.

Eliminate reflections and glare: Make sure the floor around the vehicle is matte and free of reflections. If necessary, you can use matte floor tiles or rubber mats where the calibration board is, provided they are level. Notice: High-gloss floors or metal objects can reflect light that interferes with calibration.

Make the background quiet: Position the vehicle toward a neutral background (for example, a plain wall or curtain behind the calibration board). Avoid brightly colored objects or other signs/patterns in the camera's field of view. The less visual noise, the faster and more accurately the system will recognize the calibration pattern.

Avoid moving shadows: Close doors to exclude passing traffic or people walking by (causing shadows) during calibration. A stationary, even environment is the goal.

4. Skip necessary calibrations or preparations

The error: ADAS calibration is not a step you can skip, yet it happens that garages fail to perform necessary calibrations. Sometimes calibration is omitted after a windshield replacement or bumper repair to save time or cost. In other cases, they start a calibration without first taking required preliminary steps, such as a pre-scan of error codes or wheel alignment. Skipping such essential steps can have serious consequences. For example, the ADAS system may calibrate while an underlying fault is active, or a camera may be calibrated while the car has a skewed wheel position. This leads to unreliable calibrations: the systems may appear to work, but may not function correctly when it matters.

Why does it happen? This mistake often stems from ignorance or time constraints. For example, a mechanic thinks: "The car runs fine, so that calibration will come later." - but meanwhile the driver is driving around with a misdirected safety system. It also happens that one does not have a pre-scan performs electronics, missing the fact that certain sensors have error codes or need to be recalibrated. In addition, vehiclepreparation steps sometimes ignored: consider checking tire pressure, minimizing vehicle loading, checking ride height and wheel alignment. Manufacturers prescribe these preconditions very clearly (e.g., full tank, correct tire pressure, no extra weight) to ensure that the car is in nominal condition during calibration. For example, if the suspension or alignment is incorrect, you are calibrating the ADAS system on a skewed premise - resulting in inaccurate results.

How do you prevent this?

Always calibrate when prescribed: Save a required ADAS calibration never about after repairs. Virtually all car manufacturers requirements recalibration of camera systems after a windshield replacement, for example. Not doing so can lead to erroneous or failed warnings and an increased risk of accidents. If necessary, explain the need to the customer; their safety is at stake.

Perform a pre-scan: Use a diagnostic tool to read all trouble codes (DTCs) before calibration. This reveals whether any sensors are reporting problems. Skipping such a pre-scan may mean that you are missing important problems that affect calibration. Note any DTCs and resolve them first (or take them into account during calibration). After calibration, ideally you should also do a post-scan to confirm that all systems are error-free.

Prepare the vehicle as directed: Follow factory guidelines for vehicle condition. Check tire pressure and set it to the prescribed value. Remove excess load; do not leave anyone in the car during calibration. Make sure fuel tank is adequately filled if specified by the manufacturer. These factors affect ride height and sensor perspective.

Check and adjust wheel alignment:Alignment and calibration belong together. A vehicle must first be properly aligned (tracking, camber and especially the thrust angle relative to the direction of travel) before the ADAS cameras are adjusted. If the wheels are skewed relative to the body, a perfectly calibrated camera will still look next to the markings. Alignment ensures that the car drives straight ahead; calibration ensures that the systems "look" straight ahead - both are necessary for a correct result.

5. Using improper or outdated calibration equipment

The error: ADAS calibration requires specialized equipment - from calibration boards and lasers to diagnostic tools with the right software. A common mistake is trying to calibrate with inappropriate or outdated tools. Examples include: an outdated software version on the diagnostic tester that does not properly support the new car model, or improvised calibration boards instead of or from official targets. Failure to use a stable power supply can also fall into this category: if the battery voltage drops during calibration, the procedure can fail or generate error codes. Using incorrect or uncalibrated equipment leads to inaccurate calibrations or failed procedures - and thus a false sense of security.

Why does it happen? This error usually comes from a lack of investment in tools or up-to-date knowledge. Some smaller garages do not have all the calibration kits (as they are expensive) and try to do a calibration "by feel" or with universal boards. In addition, ADAS calibration requires that the diagnostic tool be regularly updated with the latest vehicle data. If one fails to do so, the scan tool does not correctly recognize the systems to be calibrated or gives incorrect instructions. Common errors resulting are calibrations that fail because the target is not recognized, often due to improper equipment or software. In short, without proper resources, it becomes guesswork.

How do you prevent this?

Invest in the right tools: Make sure you have a complete ADAS calibration system in place - including the official calibration boards for the brands you work with, adjustable rigs, lasers and a compatible diagnostic tester. Use no homemade solutions; the patterns and dimensions of official targets are there for a reason. Good news: with us you can all ADAS calibration equipment and kits obtain so that you can work at a top level.

Keep software up-to-date: Always work with the latest software versions of your diagnostic tool. Manufacturers regularly release updates with calibration procedures for new models or improvements. An outdated scan tool can cause calibration errors or not indicate all required calibrations. For example, schedule monthly rounds of updates for all your equipment.

Train the team and follow guidelines: Even with the best equipment, mistakes can happen if the user is not properly informed. Provide training for technicians in the specific ADAS calibration procedures for each brand. Follow the manuals step by step and don't deviate from them. Also important: keep a checklist for each calibration job, noting which tools were used and whether all steps were completed - this helps consistent work and troubleshoot any problems afterwards.

Manage the power supply: ADAS calibrations sometimes take a long time (especially dynamic calibrations on the road). During static calibrations, use a battery charger or power supply to maintain on-board voltage. Too low a voltage can cause the calibration to abort or sensors to not initialize properly. Prevent this by backing up the battery (a simple but crucial measure often forgotten).

Conclusion

Proper ADAS calibration requires precision, the right environment and the right tools. Summary: measure everything out exactly, make sure you have a level floor, good lighting and prepare the vehicle correctly. Don't skip any steps and use professionally inspected equipment. By avoiding these common mistakes, you'll save yourself as a garage owner time, money and liability risks - AND ensure that your customers' safety systems do what they're supposed to do. With the right approach (and the right tools, available from us), you can make any ADAS calibration right on the spot perform so that drivers can get back on the road with confidence.

Sources: The information in this article is based on recent sources and industry expertise, including ADAS specialists and manufacturer guidelines. See citations for in-depth details and references. Every error and solution mentioned is documented to ensure that you can rely on the accuracy of this advice. Good luck with safe and accurate calibrations!